Construction Services

In today's fast paced world a majority of facilities are working with limited resources and in-house staffing for the installation and commissioning of equipment and facilities. Our approach is simple - we sit down with our clients and spend time listening and understanding the specific need. The result is that we provide a competitive service tailored to meet the specific discipline.

Our Construction Services Group can tailor a program to meet the needs of small, medium and large sized operations. Typical services include: Project Strategic Planning, Design/Engineering Layouts, Construction Activities, Project Management, Energy Modeling, Facility and Equipment Commissioning, and Validation Qualification Services.

For larger critical controlled environmental cleanroom projects or laboratory projects, we can offer our clients project management services. We assign to the project one of our senior level project managers whose key responsibilities will include but no be limited to contractual interfacing, procurement interfacing, project co-ordination/quantity surveying, project design/engineering reviews, facility commissioning & validation, and client interfacing as required to complete the assigned task.

For our pharmaceutical and healthcare clients, we offer qualification services for equipment and facilities which will can typically include:

Installation Qualification (IQ) - The IQ protocol defines the documented verification that all aspects of the installation of the unit adhere to the manufacturer's and the customer's specifications. This protocol provides a documented path that allows a traceable resource for record keeping and insures that the unit's life is maintained with equivalent components from the installation date onwards.

Operation Qualification (OQ) - The OQ protocol defines the documented verification that the unit operates as per the manufacturer's and the customer's specifications. The OQ typically includes the following; a listing on the unit's instrumentation calibration dates as well as the testing instrumentation pre and post qualification dates; a review of the availability of the unit's operation procedures as well as the following function tests; control panel verification, empty condition temperature and/or relative humidity distribution, door challenge test, power failure test and alarm test.

Performance Qualification (PQ) - The Performance Qualification defines the documentation required to demonstrate that the unit performs as per the client's specifications. The PQ should typically include the following; a listing of the unit's instrumentation calibration dates as well as the testing instrumentation pre and post qualification dates.

From the concept design phase to construction start, the final installation and commissioning of either a single laboratory incubator, a laboratory remodel or a new multi room ultra clean facility our clients have benefited from our valued construction engineering capabilities with over 30 years' experience in advanced technology, health care, and general laboratory operations in Canada and our extensive track record includes the working standards and practices of cGMP, ISO 9001, ISO 14001, ISO 13485, USP797-800, The College of Pharmacists, NAPRA compliance and Health Canada Regulations and requirements.

FEATURED PRODUCTS

HEPAire Products Corporation is pleased to feature the following Construction Services:

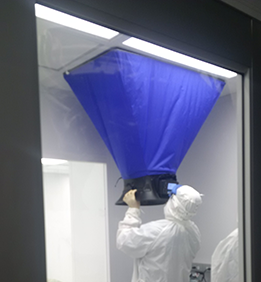

Construction Services we can provide our clients a range of clean controlled construction activities for Cleanroom and containment facilities, wet and dry laboratories, or general project construction upgrades.

If you are interested in learning more about the benefits of utilizing our Construction Services Group, please contact us or your local technical representative.

Validation Services for our pharmaceutical and healthcare clients, we offer the complete range of Validation Services from DQ, IQ, OQ, and PQ including commissioning and testing of both facilities and equipment.

If you are interested in learning more about the benefits of our Validation Services, please contact us or your local technical representative.

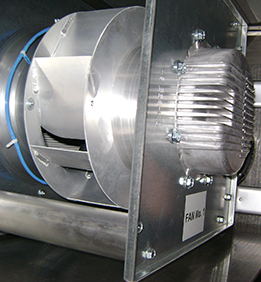

Air Energy Management Services we can provide our clients an Air Energy Management Solution for older building air deliver system increasing the existing system life cycle. We recycle and restore your base system with new interior plenum liners in vertical or horizontal configurations in a range of CFM including introduction of multiple EC fan wheel/motor technology, VFD speed control interface, access control service doors, and remote monitoring devices.

If you are interested in learning more about our Air Energy Management Services, please contact us to arrange for product demonstration by your local technical representative.